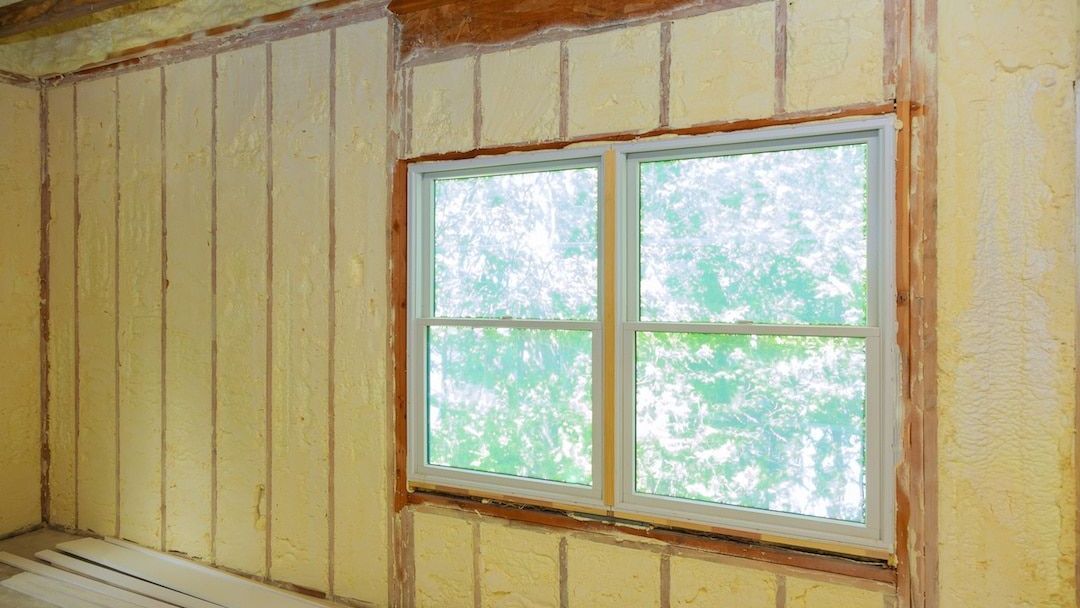

Wall Spray Foam Insulation Installation

FAQ: Installing Spray Foam Insulation in Existing Walls

How much will it cost to install spray foam insulation in my walls?

The cost of installing spray foam insulation in existing walls depends on factors like the size of the area, the type of foam used (open-cell or closed-cell), and whether your walls are easy to access. On average, prices range between $0.90 to $3.00 per square foot for open-cell foam and $1.75 to $4.50 per square foot for closed-cell foam. Other costs may include additional labor if drywall or other materials need to be removed and replaced. We will be able to provide a more precise estimate once we see your home.

How much spray foam insulation should be installed in walls?

The thickness of spray foam insulation in walls depends on the type of foam used. For open-cell foam, installers typically aim for 3 to 5.5 inches, providing an R-value between 13 and 20, which is ideal for most residential walls. For closed-cell foam, a layer of 2 to 3 inches is usually sufficient, offering an R-value between 12 and 21. The specific thickness depends on your home’s needs and local building codes.

Can spray foam insulation be installed in existing walls?

Yes, spray foam insulation can be installed in existing walls. This is done by drilling small holes into the walls (usually from the inside or outside), through which the foam is injected. The foam expands to fill the cavities, providing excellent air sealing and insulation. Once the foam is installed, the holes are patched and the walls can be restored to their original condition. There are a few types of walls that we do not install spray foam in; masonry, historical or architecturally sensitive, lath, and plaster.

How long will it take to install spray foam insulation in my attic?

The installation process for spray foam insulation in existing walls typically takes one to two days, depending on the size of your home and how many walls need insulation. This includes drilling, injecting the foam, and patching up any holes. After installation, the foam will need an additional 24 to 48 hours to fully cure.

Can I stay in my home while the installation takes place?

Yes, you can stay in your home during the installation, but it is recommended to avoid the work area while the foam is being applied and curing. The foam may release some fumes during application, so keeping windows open and staying out of the immediate area can help improve air quality. You may want to avoid the rooms where the installation is happening for 24 to 48 hours after the work is completed to ensure the foam has fully cured.

Benefits of Wall Spray Foam Insulation

Replacing your walls' insulation with spray foam insulation can offer a wide range of benefits for homeowners. Spray foam insulation is a highly effective insulation material that can provide superior thermal performance and energy efficiency compared to traditional insulation options like fiberglass or cellulose.

One of the main advantages of wall spray foam insulation is its ability to create a seamless and airtight barrier. This air seal helps to prevent air leakage, which can lead to energy loss and increased heating and cooling costs. By effectively sealing gaps and cracks in your walls, spray foam insulation can help to improve the overall energy efficiency of your home.

Additionally, spray foam insulation has a high R-value, which is a measure of the insulation's ability to resist heat flow. This means that spray insulation can help to regulate the temperature in your home, keeping it more comfortable and reducing the need for excessive heating or cooling. This can lead to lower energy bills and increased savings over time.

Another benefit of spray foam insulation for walls is its ability to provide sound insulation. Spray foam can help to reduce noise transmission between rooms and from outside sources, creating a quieter and more peaceful indoor environment.

Furthermore, spray foam insulation is a durable and long-lasting insulation solution. It is resistant to mold, pests, and moisture, making it a low-maintenance option for wall insulation replacement. Spray foam insulation can also help to improve indoor air quality by reducing the infiltration of allergens and pollutants into your home.

Overall, replacing your walls' insulation with spray foam insulation can offer numerous benefits, including improved energy efficiency, increased comfort, sound insulation, and enhanced indoor air quality. It is a cost-effective and long-lasting insulation solution that can provide lasting benefits for homeowners.

Our Wall Insulation Installation Process

- Preparation: We start by assessing the wall cavities to be insulated. Remove any existing insulation material if necessary. Ensure that the wall surfaces are clean, dry, and free of debris.

- Protection: We ensure to protect surrounding areas and surfaces that should not receive insulation, such as windows, doors, and electrical outlets, using masking tape or plastic sheeting.

- Drilling Access Holes: Depending on the construction of the walls, access holes may need to be drilled at the top or bottom of the wall cavity. These holes provide entry points for the spray foam insulation.

- Injection of Spray Foam Insulation: Our contractors and staff use specialized equipment to inject the spray foam insulation into the wall cavities through the access holes.

- Expansion and Curing: We allow the spray foam insulation to expand and cure fully. This process typically takes several hours, during which the foam will expand to fill the cavity completely and adhere to the surrounding surfaces.

- Trimming and Shaping: Once the foam has cured, we trim away any excess material protruding from the access holes using a utility knife or saw. Shape the insulation as needed to achieve a smooth and even surface.

- Sealing Access Holes: We seal the access holes using appropriate materials, such as foam plugs or sealant, to prevent air leakage and ensure airtightness.

- Cleanup: Our team cleans up any debris or waste materials generated during the installation process.

- Post-Installation Inspection: We conduct a final inspection of the insulated walls to ensure that the spray foam insulation has been installed correctly and uniformly. Check for any gaps, voids, or areas requiring additional insulation.

- Finishing: If necessary, finish the walls with drywall or other surface materials as per the building requirements and design preferences.

Revolutionize your living experience with our top-tier spray foam insulation service, designed to elevate your home's energy efficiency and comfort levels to new heights. Our dedicated team of professionals brings years of expertise to every project, ensuring precise installation of high-quality spray foam insulation throughout your entire home. Bid farewell to pesky drafts, soaring energy bills, and uneven indoor temperatures as our meticulously applied insulation seals every nook and cranny, creating a cozy and consistent climate year-round. Not only does our insulation solution enhance your comfort, but it also promotes environmental sustainability by reducing energy waste and lowering your carbon footprint. Rest easy knowing that our comprehensive insulation package is tailored to suit your home's specific needs, providing lasting performance and peace of mind for you and your family. Experience the transformative power of superior insulation with our trusted service. Interested in knowing more? Check out our Blog!